Automatic flux welding

Automatic flux welding

Welded monolithic construction

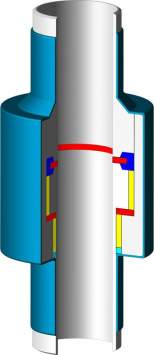

A welded monolithic construction has an enhanced capability to withstand mechanical loads and is convenient while installing and operating. U-shaped double seal system

U-shaped double seal system

U-shaped double seal system

Patented U-shaped double seal system has unique sealing and dielectric properties, and has a wide range of constructive and technological advantages as compared with O-ring seal systems:

- absence of explosive decompression effect;

- applicability under a high pressure (up to100 MPa);

- applicability at high mechanical loads (tension, compression, bending, torsion);

- possibility to manufacture large diameter joints (up to 3300 mm).

Possibility of aboveground and underground installation

Insulating monolithic joint with operating temperature of up to +250°С

Insulating monolithic joint with operating temperature of up to +250°С

Applicability in all the climatic zones

Applicability in all the climatic zones including maximum operating temperature up to plus 250°C.

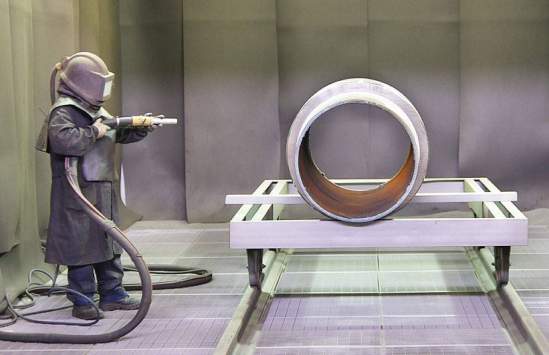

Shot peening before coating

Shot peening before coating

Factory outer coating

Factory outer coating (epoxy or polyurethane) provides an effective electrical and mechanical protection against external influences.

Nonconductive inner coating

Nonconductive inner coating allows to avoid a bypass during the transportation of a conductive product. Tests for internal pressure combined action and torque

Tests for internal pressure combined action and torque

IMJ are subjected to the following types of tests

Acceptance tests and inspections. 100% of manufactured IMJ are subject to:

- Non-Destructive Testing of Welded Seams

- Internal hydraulic pressure test

- Internal hydraulic pressure cycle testing (upon Customer's request)

- Internal hydraulic pressure integrity test

- Breakdown test

- Electric resistance test

- Thickness test of anticorrosive coating

- Dielectric continuity test of anticorrosive coating

- Overall dimension and weight test

- Visual inspection

Tests for internal pressure combined action and torque

Tests for internal pressure combined action and torque

Periodic testing (Once in 5 years). Tests are performed on IMJ of different diameters and pressure levels to confirm the design reliability of the entire range of products (randomly)

- Tests for internal hydraulic pressure combined action and bending moment

- Tests for internal hydraulic pressure combined action and torque